Table of Contents

The camshaft is one of the most important parts of the internal combustion engine that regulates the opening and closing of the inlet and exhaust valves. This article explains the camshaft function, working, parts, and applications.

What is a Camshaft?

A camshaft is a rod featuring a series of protruding cams, designed to transform rotary motion into linear motion.

In the case of an engine, a camshaft is a part of the engine that regulates the opening and closing of an IC engine’s inlet and exhaust valves. A camshaft has more than one cam. It has many radial cams, which displace the inlet or outlet valve. This cam slides over the inlet and exhaust valves.

The cam transforms the rotary motion of the camshaft into the reciprocating movement of the filter or follower. This shaft allows the suction and discharge of the fuel inside the engine.

The crankshaft transfers motion to the camshaft through gears, chains, or belts. This ensures the valve timing with respect to the movement of the piston.

The camshaft operation depends on the working of the cam and the functioning of the valve. The inlet and outlet valves install on the cylinder head, and cams are installed on these valves. The cylinder head blocks the nozzle, which permits the fuel suction or discharge and needs reciprocating movement.

In simple words, a cam is a unit that transforms rotary motion into linear motion and vice versa. The cam on the camshaft achieves displacement with a radial turning pattern and a follower moving vertically to the axis of rotation. The position of the camshaft varies according to the design of the engine.

How does Camshaft work?

The main function of the camshaft is to open the suction valve and exhaust valve at the appropriate time. The crankshaft drives to this shaft. It is linked with the crankshaft through a belt or meshing gears.

The movement of the camshaft is slower than the crankshaft. It completes one revolution after two revolutions of the crankshaft. In a four-stroke engine, a camshaft works in the following way:

- As the piston moves from TDC to BDC (downward), it transfers its motion to the crankshaft.

- The crank receives piston motion and transforms this motion into rotary motion, and starts rotating.

- The crankshaft is connected to the camshaft through a gear or belt.

- As the crankshaft transfers its rotary motion to the camshaft, the camshaft converts this rotary motion into reciprocating motion and presses the inlet valve, and opens it.

- As the valve opens, the fuel starts to enter the combustion chamber.

- After suction and compression strokes, the combusted air-fuel mixture expands in the chamber, which forces the piston to move downward.

- During the downward motion of the piston, again, the crankshaft receives motion and moves the camshaft.

- As the cam of the exhaust valve receives this motion, it presses the exhaust valve and opens it, which allows exhaust gases to move out of the combustion chamber.

Camshaft Construction Material

The solid material is most commonly used for the manufacturing of the camshaft. This is because such camshafts provide great rigidity. Cast iron is also used for the manufacturing of camshafts because cast iron delivers more strength.

The camshafts made of the chilled iron process can provide excellent wear resistance because the chilling method hardens the material. Different materials mix with iron to generate the most appropriate features for their applications.

Some industries also utilize billets when less production and excellent quality are needed. But this process demands high time and cost compared to other processes. These shafts manufacture through machining, casting, or forging on milling and lathe machines. They are manufactured by forging, casting, and machining on lathes and milling machines.

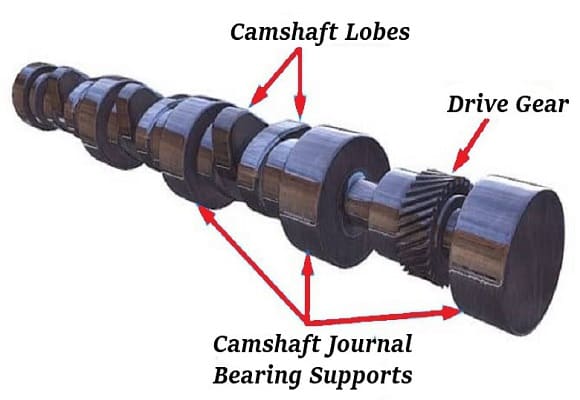

Components of Camshaft

The camshaft has the following major components:

- Cam

- Cam follower

- Main journal

- Lobe

- Ends

1) Cam follower

It is a special type of needle bearing or roller that follows the cam lobe profile. It is also called track follower. There are different configurations of the cam follower, but the most important feature is the attachment of the cam follower to the mating part. The yoke cam follower has a hole in the center, and the stud cam follower uses a stud.

In the absence of this camshaft part, the cam is not very useful because the cam takes support from the follower to convert rotatory motion to reciprocating motion. The followers have cam follower bearings that enable the cam follower to convert rotary motion into reciprocating.

The follower bearings also have different designs but are usually manufactured with a very thick outer ring. This thick outer ring design of the bearing permits the follower to absorb high radial loads, while soft cores can withstand high loads without the risk of component damage.

The cam follower requires balls or needles and special materials such as chrome or stainless steel according to the requirements of the application.

2) Cam

A cam is a device that transfers the required movement to a follower through direct contact. The main objective of this camshaft part is to transform the crankshaft’s rotary motion into linear motion.

It has a non-circular design with a single lobe. The follower gets the movement by the cam as it turns. Each engine’s camshaft has more than one cam.

The cam is installed on the valves. It is responsible for regulating the opening and closing of the intake and exhaust valves.

The cam timing is very important for the performance of the IC engine. The rotation of the cam opens the cylinder’s suction valve and exhaust valve. The proper timing of the cam is very important to ensure that fuel is injected and expelled at the right time.

3) Main Journal

The main objective of the main journal is to maintain the position of the camshaft when it rotates around the engine.

4) Lobes

The camshaft lobes spin according to the movement of the piston. The speed of this component varies according to the speed of the engine. The main objective of the lobes is to open and shut the inlet and outlet valves.

5) Ends

The front end of the camshaft is designed in such a way it links the belt with the crankshaft. The cam’s rear end uses a special gear to rotate the motor distributor. The ignition timing is the same as the rest components of the engine.

6) Bearing

The bearing installs with the engine main hornet. It prevents the camshaft from destroying the engine block if the engine fails. The bearings assist in maintaining perfect camshaft rotation.

Types of Camshafts

The camshaft has the following major types:

- Based on lifters used by the camshaft

- Based on the camshaft driver member shape

Based on lifters used by the Camshaft

1) Flat Tappet Cam

A flat tappet cam is not flat in reality. These cams contain a small crown on the face. It is installed where the lifter and lobe move oppositely to each other, and the lifter rotates on the lobe. The lobes of this cam are manufactured in a small tapered design.

The lifter must be turned to the lobe in order to avoid unnecessary and damaging wear. In contrast to roller tappets, flat tappet has low weight and less mass. It is easy to guess that the flat tappet is at the dead lobe center of the cam lobe. These cams are cheaper than roller cams. Due to this reason, flat cams are more attractive.

2) RollerCams

The rounded tip of the roller cam allows the roller to hold the valve open for extended periods of time at high lift, which affects fuel-air mixture requirements. The shape of the lobe also allows the valve to open more quickly.

The main advantage of these camshafts is that they decrease inner friction, permit a more violent cam profile, and favor high speeds. These have very high durability. In other words, it has an unlimited useful life.

Roller cams can be reused again and again. They reduce friction and increase power. It also increases service life by reducing wear and tear.

Based on the camshaft driver member shape

1) Cylindrical Cam

This type of cam has a cylindrical shape. It is also known as a barrel of drum cam. The surface of the cylindrical cam has a groove cut. The cam follower uses this groove cut for its motion.

This camshaft has a cam’s axis parallel to the direction of the follower member’s motion.

2) Radial Cam

A radial cam is also called a plat or disk cam. It is known as a radial cam because it has an axis perpendicular to the direction of the follower’s movement.

This type of cam has an irregular contour plate. This plate uses to convert the motion of the cam to the cam follower or driven member motion.

3) Conjugate Cam

It has 2 rollers. The follower or driver of this camshaft is linked with these rollers. The rollers tend to limit the movements of others so that they can remove noise and produce quiet operations.

These cams use in applications that need the quiet working of the camshaft.

4) Globoid Cam

This cam has a very similar design to a cylindrical cam. The main difference is that the cylindrical cam replaces via a concave or convex assembly.

5) Spherical Cam

The spherical cam has a groove on its curved design. It has a spherical shape. The follower runs across the groove. The movement of the follower is vertical to the rotational axis of the spherical cam.

6) Translating Cam

This cam contains a grooved contour plate. The follower members oscillate along the cam groove surface.

7) Heart-shaped Cam

It is known as a heart-shaped cam because it has asymmetrical heart-shaped. The follower runs along the cam edge. It has smooth and continuous motion. Such a type of cam is most commonly depleted to wound the cable across the solenoid squarely.

8) Wedge Cam

The end of this cam has a pointed shape and a wide basem*nt. The driver has a sliding movement relative to the cam.

9) Spiral Cam

It is a spiral semi-circular contour that contains a groove on its surface. The follower of this cam has a perpendicular movement according to the driver member’s linear movement of the camshaft.

Causes of a bad Camshaft

There are multiple reasons for the camshaft failure. The most reasons for the failure of the camshaft are given below:

- Due to the wrong pressure of the valve spring.

- Because of lobe wear.

- Insufficient brake-in.

- Due to the damaging of the cam.

- Due to the large axial play of the camshaft.

- Use of oil filter with the new cam.

- Due to mechanical interference such as seal interference, spring coil bind, valve and piston interference, rocker arm grooves, and screw interference.

- Low-quality use of camshaft material.

Driving Mechanism of a Camshaft

The camshaft gets driving power by the crankshaft. The crankshaft delivers its power to the camshaft through different means and drives it. The camshaft driving mechanism is given below:

- Chain Drive

- Gear Drive

- Belt Drive

1) Chain Drive Mechanism

In this mechanism, a chain sprocket is utilized to deliver the crankshaft power to the camshaft.

If the distance between the crankshaft and the camshaft is large, a chain drive mechanism is operated.

In this mechanism, the camshaft and crankshaft move in an identical direction. It uses a chain tensioner to prevent the chain system from coming loose because loose chains cannot transfer sufficient power from the crankshafts to the camshafts.

2) Gear Drive Mechanism

The gear drive mechanism is used where is a required minimum distance between the crankshaft and camshaft. In this mechanism, a gear drive method uses to deliver the crankshaft’s power to the cam.

In the case of the gear drive mechanism, the crankshaft’s driver gear meshes with the camshaft’s driven gears (as you can see in the below-given diagram). As the crankshaft starts rotating, it delivers power to the camshaft through the driver gear. As the driver gear rotates, it further rotates to the driven gears, which opens and close the inlet and exhaust valves of the engine.

3) Belt Drive Mechanism

The working of the belt drive mechanism is very identical to a chain drive mechanism. There is only a little bit of variance between these two mechanisms, and a belt mechanism uses a belt for transferring crankshafts power to the camshafts while a chain drive mechanism uses a chain.

FAQ Section

What is the function of a camshaft?

The main function of the camshaft is to open the inlet and exhaust valve of an engine by converting the rotary motion of the crankshaft into a reciprocating motion.

A camshaft works on which driving mechanism?

A camshaft uses the following three main mechanisms to receive power by the crankshaft:

- Belt drive mechanism

- Gear drive mechanism

- Chain drive mechanism

Why is a camshaft needed in an engine?

The piston engines can’t work without a camshaft. A machine is needed a camshaft for the proper opening and closing of the inlet and exhaust valves.

What is the function of a camshaft?

The main function of the camshaft is to open the inlet and exhaust valve of an engine by converting the rotary motion of the crankshaft into a reciprocating motion. The camshaft controls the breathing of the engine – it manages the intake of the air-fuel mixture into the cylinders for combustion and the expulsion of exhaust gases after combustion.

What are the applications of a camshaft?

In reciprocating engines, the camshafts use to close and open the suction and exhaust valves.

What are the signs of a bad camshaft?

- Engine stalling

- The vehicle won’t start

- The vehicle moves slowly

- Cylinder misfire

- Poor fuel economy

- A reduction in the engine power

- Metal debris in the engine oil

- Check engine light illumination

What are the parts of camshaft?

- Cam lobes

- Base circle

- Camshaft ends

- Bearings/bearing journals

- Camshaft ends

- Lifters

What causes a camshaft to fail?

- Insufficient lubrication

- Poor Manufacturing

- Wear and Tear

- Wrong Installation

- Mechanical Over-revving

- Contaminated oil

- Engine Overheating

Can a car run with a bad camshaft?

Yes, your car can run with a bad camshaft, but it’s not recommended. The camshaft is crucial for opening and closing the engine’s valves to allow for the intake of air and fuel and the expulsion of exhaust gases. If the camshaft is damaged, it can lead to poor engine performance or even engine failure.

Read More

- Piston Construction and Function

- Crankshaft Working and Parts

- Symptoms and Causes of a Bad Camshaft Sensor

- Symptoms and Causes of a Bad Crankshaft Sensor